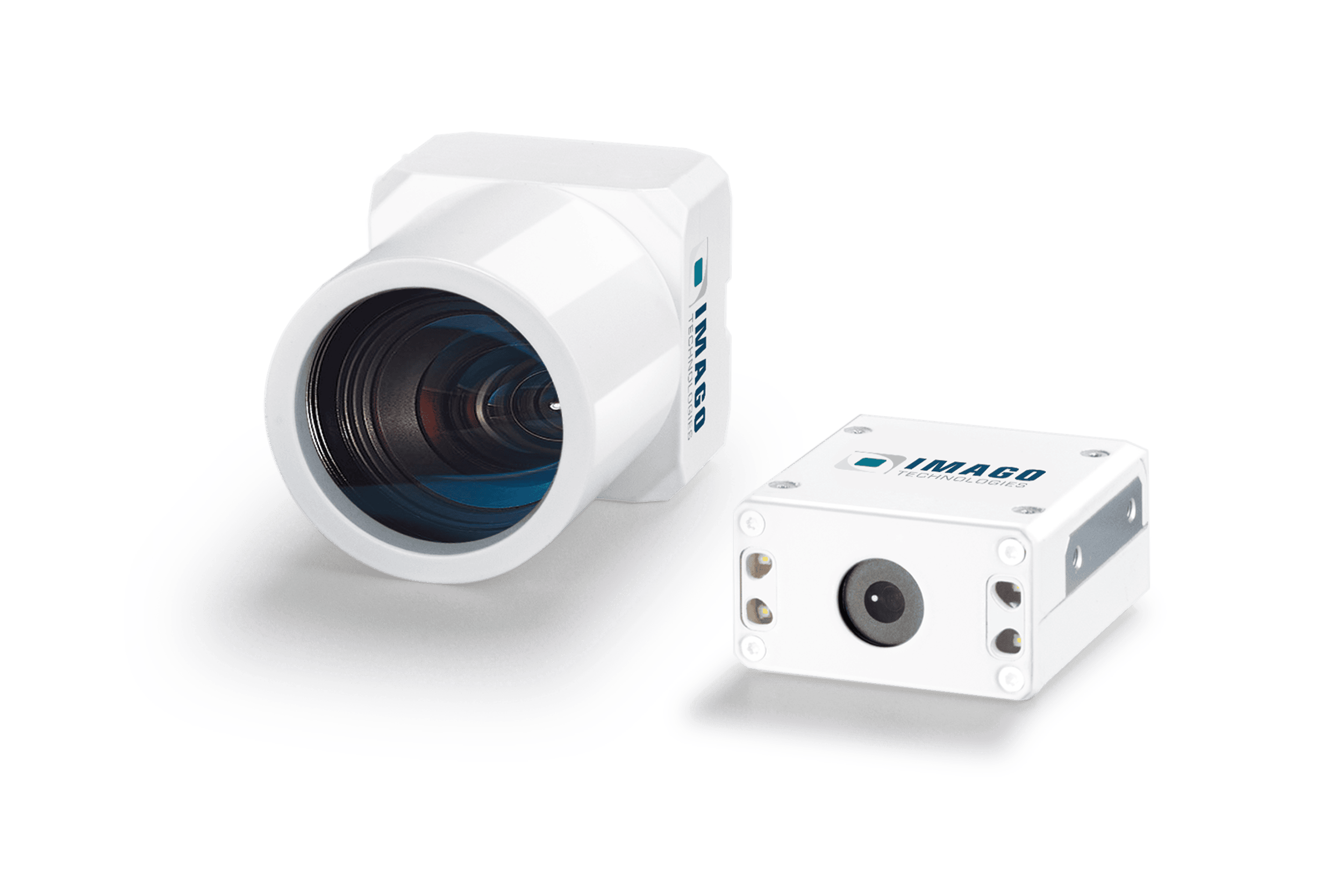

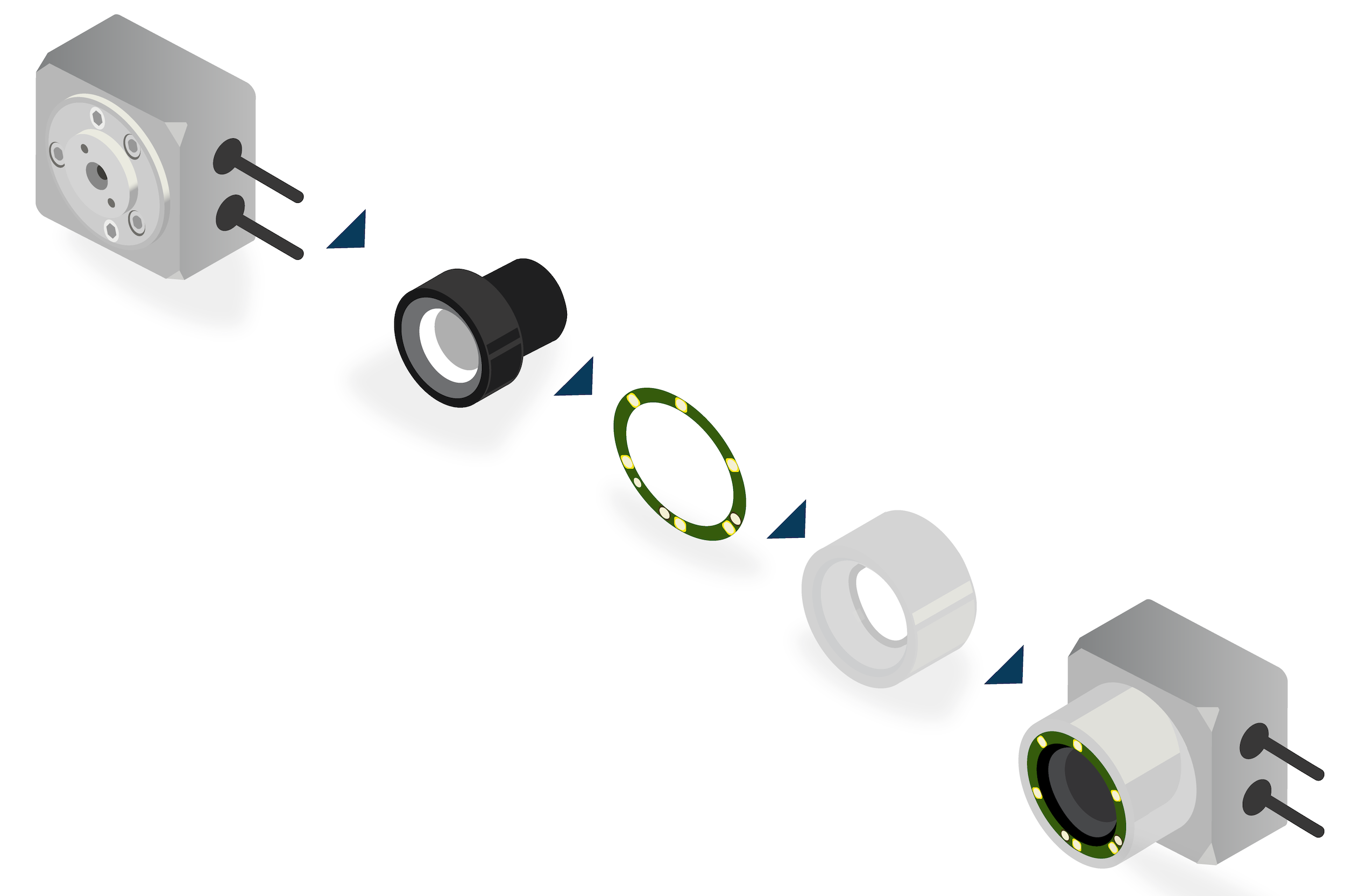

Our vision sensors combine camera, illumination, processor, and interfaces in a compact housing – freely programmable for maximum flexibility and quick integration into your production line. IMAGO’s vision sensor solutions ensure seamless integration into industrial applications. Ideal for anyone who needs a compact design without compromising performance or adaptability.

Vision Sensors

FILTER

- Extremely compact

- Freely programmable complete solution

- Ideal for simple inspection tasks

Compact, powerful, industry-ready

Integrated intelligence for fast results

Easy programming with ViewIT

Ideal for series applications with customization potential

Vision Sensors – as simple as possible, as versatile as necessary

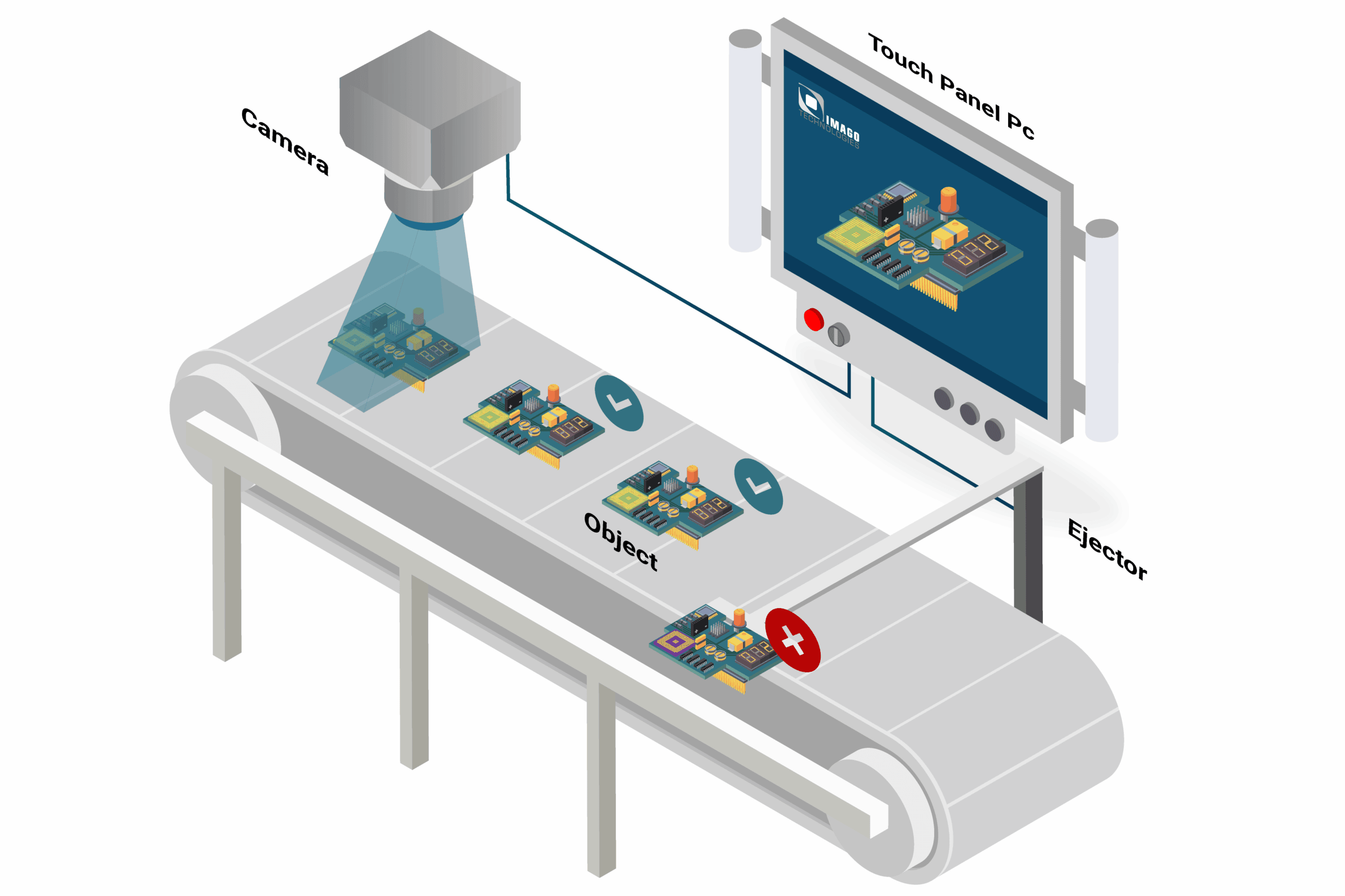

IMAGO vision sensors combine the ease of classic sensors with the versatility of a complete image processing system. Thanks to integrated camera, processing, illumination, and interfaces, each device works independently – no external PC required.

Commissioning is fast, configuration is intuitive, and open programmability allows tailored solutions for every application.

Technology in focus: free programmability for maximum flexibility

The free programmability of our visual sensors is a key advantage: algorithms, inspection processes, and evaluation logic can be customized to your needs.

From advanced quality control to barcode reading or surface inspection – with the open ViewIT software platform and powerful hardware such as the Vision Sensor LM, you can build precise solutions for your production environment.

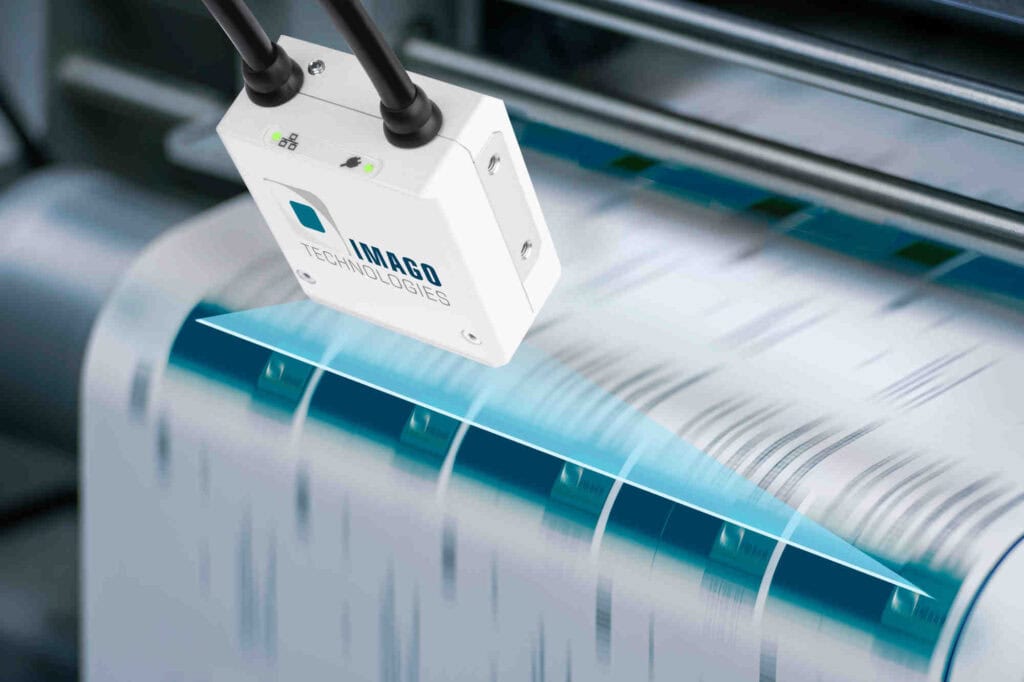

Industry versatility – from pharma to printing

In the pharmaceutical industry, vision sensors support track & trace and ensure reliable drug packaging. In food & beverage production, they monitor labels and detect foreign objects.

In logistics, they read codes, check address labels, and count products on conveyors. In the printing industry, they guarantee high-speed quality control and detect even the smallest deviations. Their compactness and flexibility make them ideal for both standard and custom applications.

Why choose IMAGO Vision Sensors?

Our vision sensors are developed and manufactured in Germany, specifically for industrial use. They combine robust, long-life hardware with flexible software support. Systems are designed for long-term availability and optimized for series integration.

With decades of industry experience, IMAGO delivers more than hardware: individual consulting, collaborative engineering, and ready-to-use image processing solutions for your production line.

FAQs about Vision Sensors

What makes a vision sensor different from a standard camera?

A vision sensor integrates camera, illumination, and processing in one device, eliminating the need for external PCs – ideal for space-constrained or decentralized setups.

What’s special about programming with ViewIT?

ViewIT allows development without traditional coding. With a graphical user interface and ready-to-use modules, customized solutions can be built quickly.

What are the benefits of freely programmable vision sensors compared to single-task preconfigured models?

Freely programmable vision sensors offer flexibility and expandability – ideal when inspection tasks change or additional features are required.

Which applications are vision sensors suited for?

They are suitable for diverse inspection, testing, and detection tasks – in logistics, packaging, printing, and pharma.

Can a vision sensor be integrated into existing systems?

Yes. All IMAGO vision sensors are designed for industrial interfaces and easy integration, such as M12 connectors or standard operating systems like Linux.