Embedded computers from IMAGO combine high computing power with industrial-grade robustness in a compact, fanless design. Whether for classic image-processing algorithms or GPU-accelerated AI applications, our systems offer versatile interfaces, real-time capability, and long-term availability.

Embedded Computer

FILTER

- Real-time I/O & LED controller

- Variants for all common interfaces

- Compact, passively cooled housing

- Vision Panel-PC

- Vision Box and HMI in one device

- All-in-one solution for easy operation

Real-time capable thanks to RTCC

Long-term availability guaranteed

Compact & fanless

Flexible for every camera

Embedded Computers for Industrial Image Processing – Performance Meets Compactness

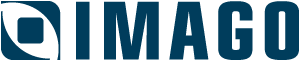

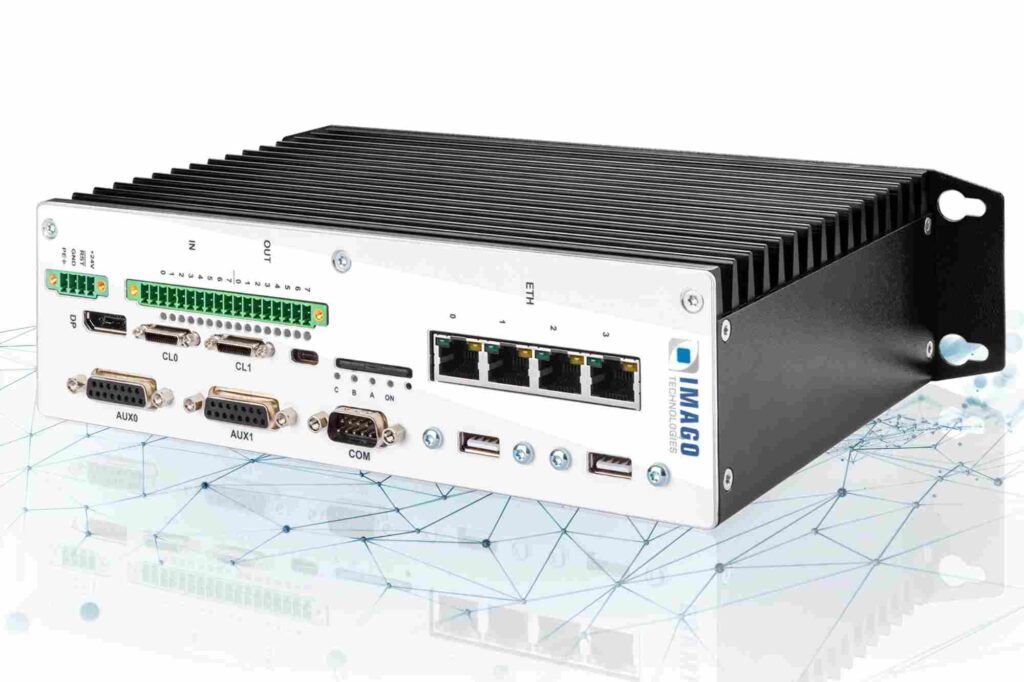

IMAGO embedded computers deliver high processing power — depending on the model with up to 12 ARM CPU cores or powerful Intel i-Core processors — combined with industrial-grade features. Thanks to their fanless design, robust housings, and wide interface variety, they are ideal for demanding production environments.

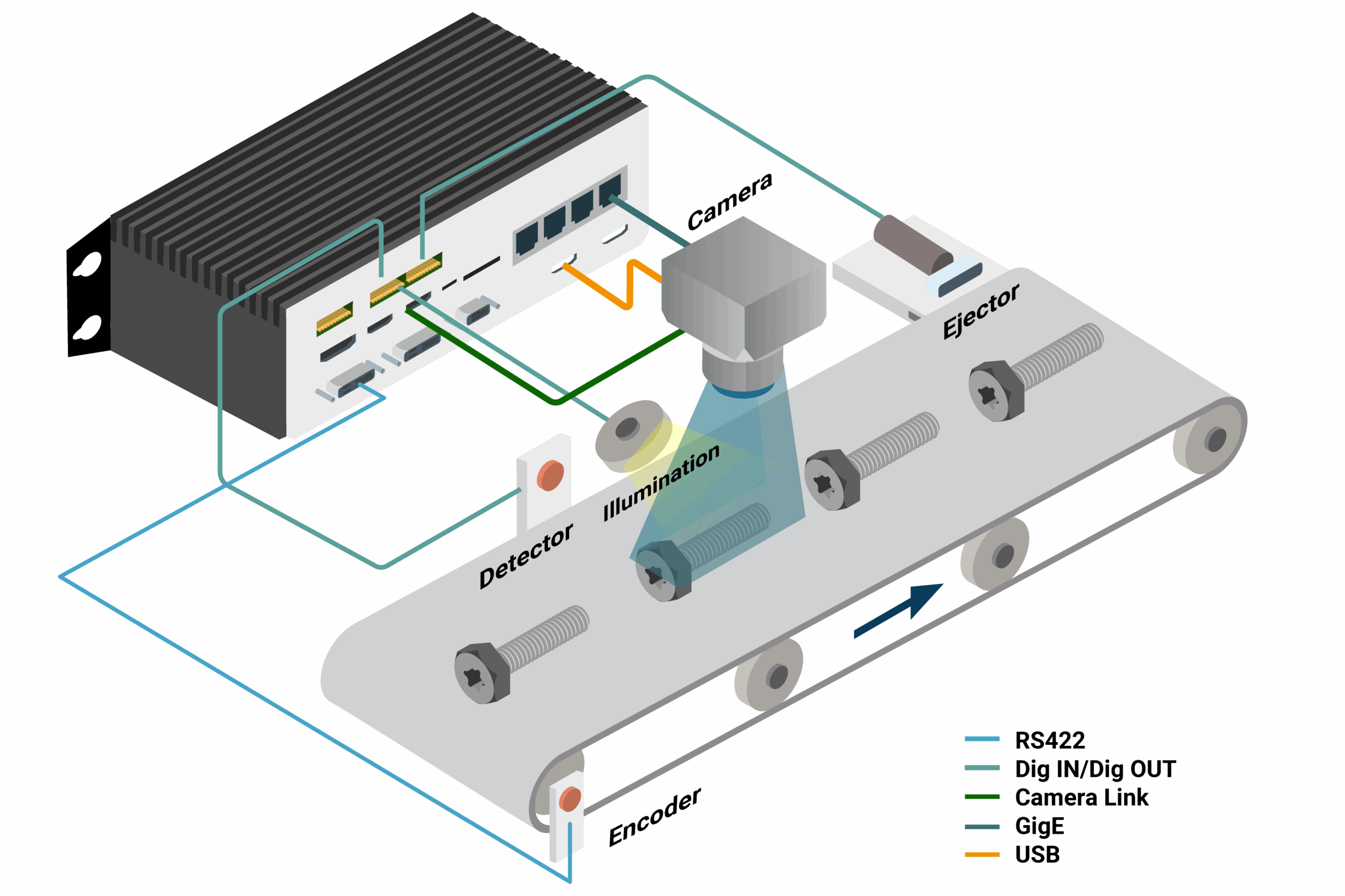

The product range includes platforms focused on GPU-accelerated vision, classic industrial embedded PCs with integrated illumination and I/O control, and touch-based HMI solutions. They support Camera Link, GigE Vision, 5GBase-T, real-time I/O, Ethernet, and CAN.

Technologies for Maximum Performance

The Real-Time Communication Controller (RTCC) is integrated into all embedded PCs and operates independently of the operating system. It ensures deterministic processing of input and output signals, for example to synchronize lighting and camera or to trigger actions based on encoder signals.

Panel solutions like the Vision Box Touch combine a touchscreen, real-time applications, and CPU performance in a single device — ideal for decentralized operation close to the camera system.

Versatile Industrial Applications – From Pharma to Logistics

IMAGO embedded computers are used successfully across numerous industries:

In food and packaging, they detect labels or verify presence; in pharmaceuticals, they inspect blisters and codes; in electronics manufacturing, they check minuscule components. Printing applications also benefit from their real-time capability and flexibility.

Thanks to variations in interfaces, form factors, and software integration, these systems are suitable for both high-volume series applications and customized solutions.

Why Embedded Computers from IMAGO?

IMAGO designs and manufactures embedded computers in Germany — tailored specifically to the requirements of manufacturing, automation, and inspection. All devices offer industrial vision interfaces, RTCC for real-time control, and SDKs for Linux and Windows.

Through close cooperation with machine builders, OEMs, and high-volume customers, IMAGO provides proven complete solutions with technical consulting, customization options, and long product lifecycles. This makes IMAGO embedded PCs a solid foundation for smart machine-vision systems.

FAQs About Embedded Computers

What is the difference between embedded vision PCs and conventional vision PCs?

A conventional vision PC is a versatile computer adaptable through expansion cards and designed for protected industrial environments. In contrast, an embedded vision PC is a compact, fanless specialist with integrated industrial interfaces — built for maintenance-free 24/7 operation directly inside the machine.

What is an embedded computer for industrial image processing?

An embedded computer is a compact industrial computer with tailored processing power and interfaces for machine-vision applications — fanless and designed for long-term availability.

What does RTCC mean in embedded computers?

The Real-Time Communication Controller (RTCC) ensures precise control of all inputs and outputs independently of the operating system — essential for deterministic real-time processes.

How does an embedded vision computer work?

A sensor captures visual data, an integrated processor (often a microcontroller, SoC, or FPGA) analyzes it, and specialized software — often enhanced by AI algorithms — performs the required inspection. The system can detect objects, take measurements, or trigger actions based on the image analysis.