IMAGO’s AI cameras combine powerful image processing and modern deep learning technology in a compact system. They analyze visual data directly on the device, enable fast decisions without an external computer, and integrate easily into industrial processes.

AI Cameras

FILTER

- Edge AI with Google Coral

- For fast prototype development

- Ideal for experienced AI developers

Classifies complex features

Integrated deep learning technology

Ideal for changing product variants

Robust hardware for industrial use

Variety and Technology of Modern AI Cameras

IMAGO’s AI cameras combine camera, processing unit, and software in one compact system. Depending on the model, you get either a turnkey deep learning solution (Vision Cam AI.go) or a freely programmable inference system (Vision Cam AI, Vision Cam XM2, Vision Cam LM2).

The systems feature 5 MP or 12 MP sensors, support Gigabit Ethernet, and offer flexible digital I/Os. Thanks to their small form factor, they are also suitable for tight installation spaces.

Deep Learning in Industrial Image Processing

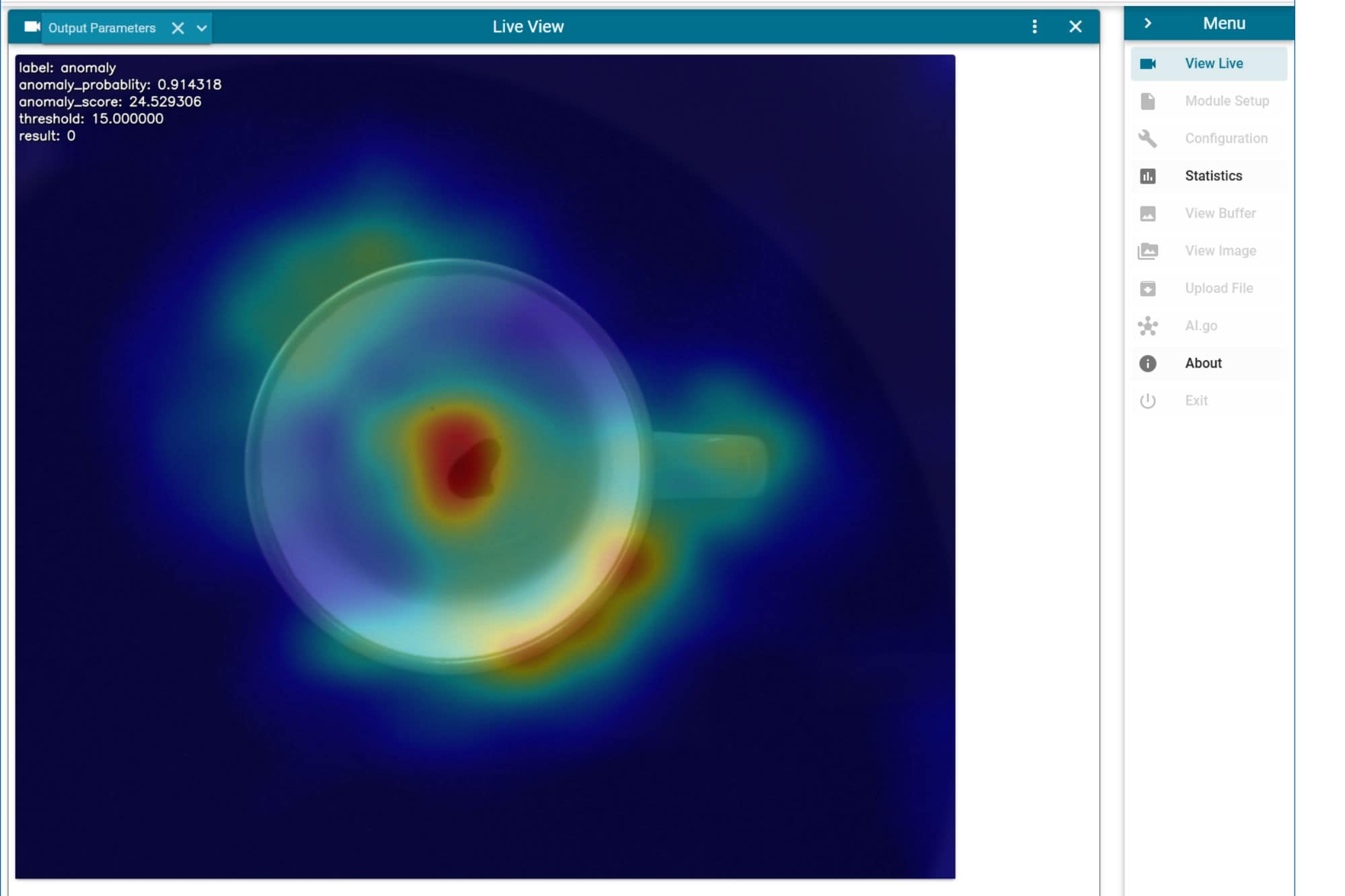

Unlike traditional rule-based vision systems, AI cameras learn visual features from examples. This makes them ideal for applications with difficult-to-formalize defect patterns or natural variations.

With an integrated web GUI (Vision Cam AI.go), open hardware (Vision Cam AI), the NVIDIA Orin platform for real-time processing (Vision Cam XM2), or a high-speed line scan camera for ultra-fast inspections (Vision Cam LM2), applications can be quickly set up or individually developed.

AI Cameras in Industry: Flexible & Adaptable

IMAGO’s AI cameras are used in a wide range of industries: in the food industry, they inspect visually variable products; in the pharmaceutical sector, they detect the smallest defects on ampoules or packaging. In electronics manufacturing, they support solder joint inspection, and in logistics, they capture packaging units and codes.

Thanks to deep learning, the cameras handle tasks where rule-based systems reach their limits. Flexible customization options enable quick adjustments to new products or variants.

Why Choose IMAGO AI Camera Solutions?

IMAGO develops and manufactures all AI cameras in Germany. The systems are tailored to industrial requirements: robust, integration-friendly, and future-proof.

We offer comprehensive technical consulting, industry-specific expertise, and decades of experience in industrial image processing.

FAQs about AI Cameras

What is an AI Camera?

An AI camera combines an image sensor, processor, AI accelerator, and AI software in a compact system. It can independently analyze images and is ideal for industrial inspection tasks with complex requirements.

What does “AI Camera” mean in practice?

An AI camera uses deep learning for image evaluation – without classic rule definitions. This enables it to detect deviations or defects that are difficult to formalize.

When is an AI Camera better than traditional image processing?

An AI camera is preferable when inspection features are complex or variable – for example, natural objects, defects without a clear shape, or changing product series.

How does Vision Cam AI differ from Vision Cam AI.go?

The Vision Cam AI is ideal for developers with AI experience, while the Vision Cam AI.go is designed for end-users without programming knowledge – both rely on deep learning.