With an Industrial Dashcam, you clearly see critical machine moments – exactly when they happen. The Industrial Dashcam records event-driven, provides slow-motion for root cause analysis, and prevents data overload. This reduces downtime and speeds up service and commissioning.

Industrial Dashcam

FILTER

- High-speed video for condition monitoring

- 1,000+ frames per second

- for maintenance and fault analysis

- Ultra-compact observer for processes

- ring buffer & trigger

- H.264 encoding / streaming

Event-driven recording

Trace errors quickly

No data overload

Easy to integrate

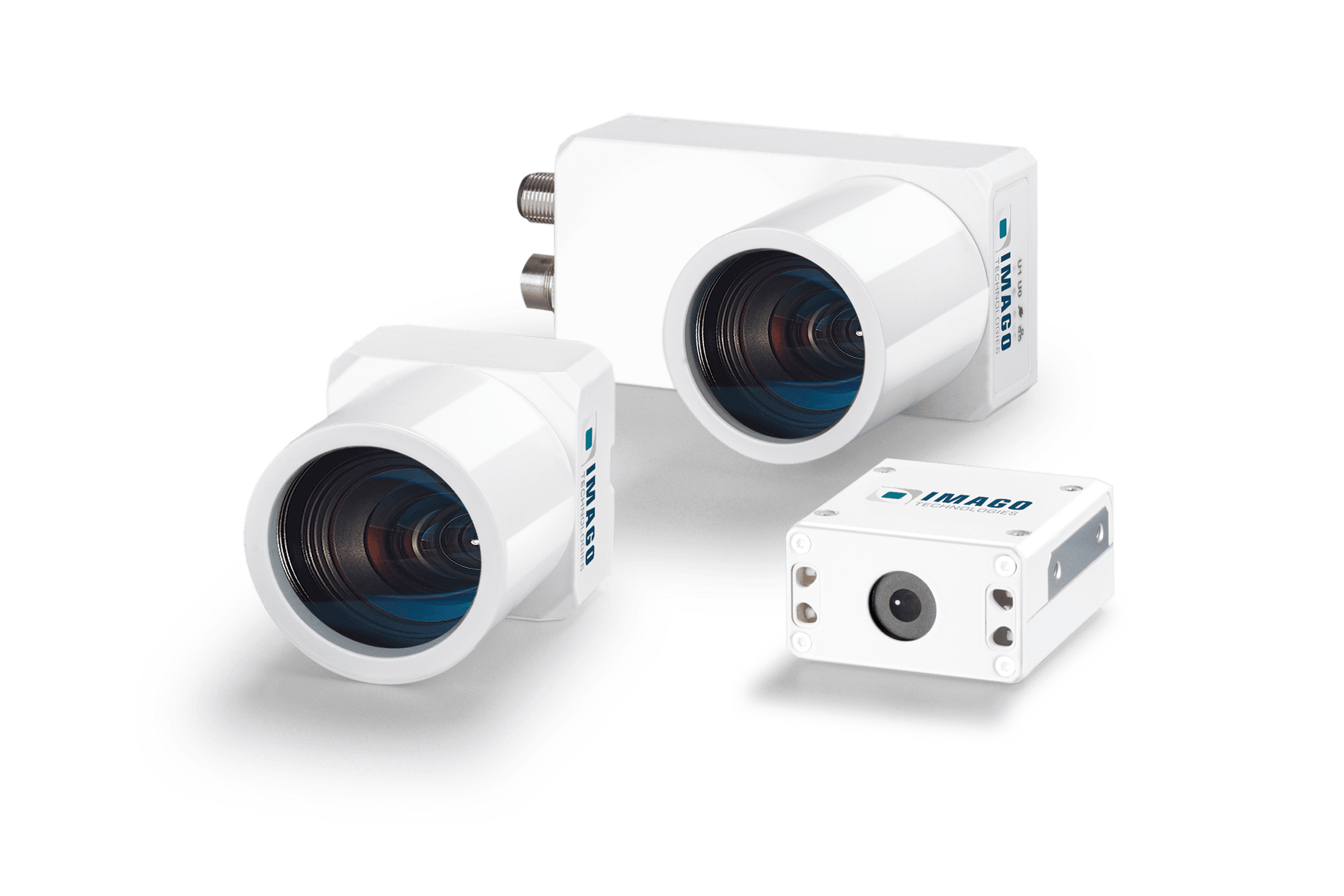

Variety and Technology of Industrial Dashcams

IMAGO Dashcam systems do not record continuously, but selectively: before, during, or after a trigger. The Industrial DashCam stores up to 300 s of video per event and provides live view in the browser or an H.264 stream. Export is handled easily via Gigabit Ethernet – focused sequences instead of terabytes of continuous recordings.

Depending on requirements, choose between the compact Industrial DashCam and the Industrial DashCam 1000. Typical use cases: condition monitoring, end-of-line documentation, machine setup, predictive maintenance, and remote maintenance.

Technology Focus: Trigger, Ring Buffer & Slow Motion

The ring buffer keeps the relevant time window ready. With freely selectable trigger modes, you record exactly the sequences that reveal the root cause. Storage in the standard video format H.264/MPEG-4 allows smooth slow-motion analysis in common players.

Configuration is done via the web GUI; both models operate stand-alone and can be integrated into existing environments via REST API, I/O, and GigE. The Industrial DashCam runs on an ARM processor, while the Industrial DashCam 1000 uses NVIDIA Orin NX – ideal for high frame rates and powerful processing.

Industrial Use: from Standard to Specialized Applications

In food & beverage, pharma, manufacturing, packaging & logistics, or printing, the Industrial Dashcam visualizes fast processes: cycle delays, misalignments, filling and folding operations, palletizing, or conveyor belt malfunctions. Slow-motion sequences make mechanics and handling transparent.

For remote analysis and highly dynamic processes, the Industrial DashCam 1000 provides significantly higher frame rates – ideal for condition monitoring and diagnostics during operation. This way, teams identify root causes faster, avoid unplanned downtime, and reduce service and travel costs.

Why Industrial Dashcams from IMAGO?

30+ years of machine vision expertise: IMAGO develops hardware for industrial image processing with a focus on miniaturization, high frame rates, powerful computing, and energy-efficient systems. The result: reliable dashcam solutions that integrate seamlessly into machines, lines, and plants.

Compact & industrial-grade: The Industrial DashCam fits exactly where it is needed – including LED strobe, trigger inputs, and browser operation. The Industrial DashCam 1000 combines C-mount optics with high computing power – designed for flexible optical setups and fast processes.

FAQs about the Industrial Dashcam

What is an Industrial Dashcam and what is it used for?

An Industrial Dashcam is an event-driven industrial camera with a ring buffer. It records short, relevant sequences – not endless streams. This helps you better understand machine behavior, document end-of-line tests, and avoid unnecessary data volumes while maintaining high analysis quality.

How do triggers and the ring buffer work in practice?

Using freely selectable trigger modes, the camera records automatically. Thanks to the ring buffer, you can capture video before, during, or after the event.

Do Industrial Cameras Require Special Lighting?

Yes, for precise and repeatable results, industrial cameras require specially coordinated lighting. It ensures clearly recognizable features, reduces reflections, and prevents misclassifications. While high-quality industrial cameras can deliver good images even under unfavorable lighting conditions, optimal illumination remains a key factor for stable inspection processes.