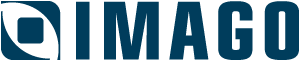

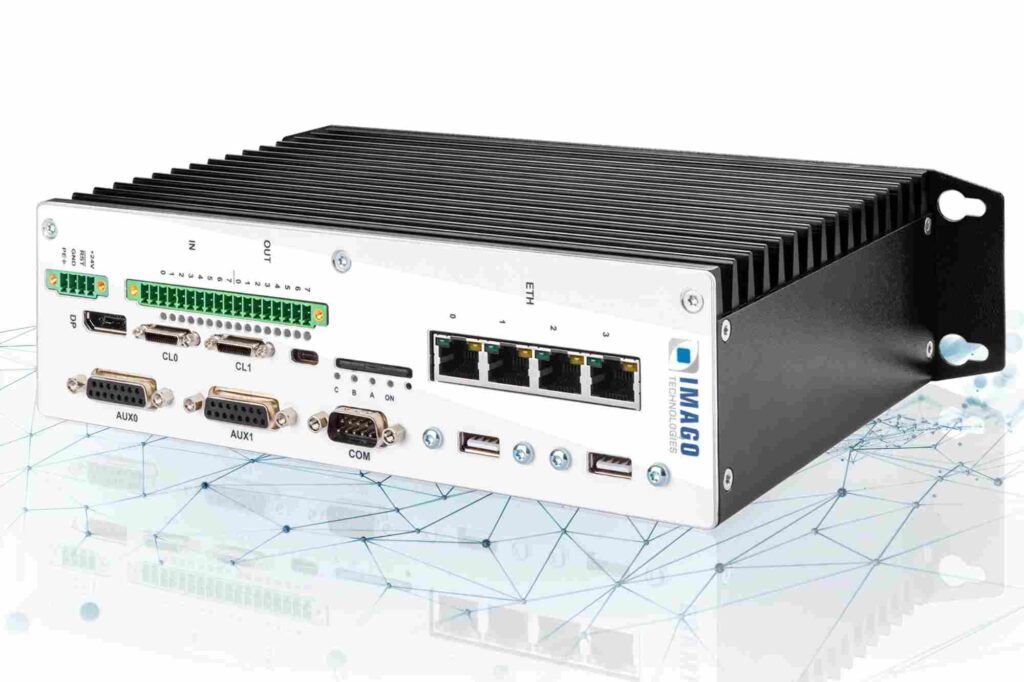

Industrial PCs from IMAGO combine computing power, real-time capability, and robust design – specially developed for demanding image processing tasks. They integrate a wide range of interfaces, trigger logic, and long-term availability in a compact, fanless design.

Industrial PC

FILTER

- Real-time I/O & LED controller

- Variants for all common interfaces

- Compact, passively cooled housing

- Vision Panel-PC

- Vision Box and HMI in one device

- All-in-one solution for easy operation

Reliable in real time

Flexibly adaptable

Developed for AI & ML

Compact & durable

Powerful Industrial PCs for Image Processing & Automation

With integrated camera interfaces, high computing power, and industrial connectivity, our Industrial PCs support demanding inspection, measurement, and control tasks – even in harsh environments.

With a variety of CPU, GPU, and interface options, IMAGO systems can be tailored precisely to your application. Typical use cases include surface inspection, code reading, and AI-based hyperspectral analysis.

Integrated Intelligence & Real-Time Capability Directly in the IPC

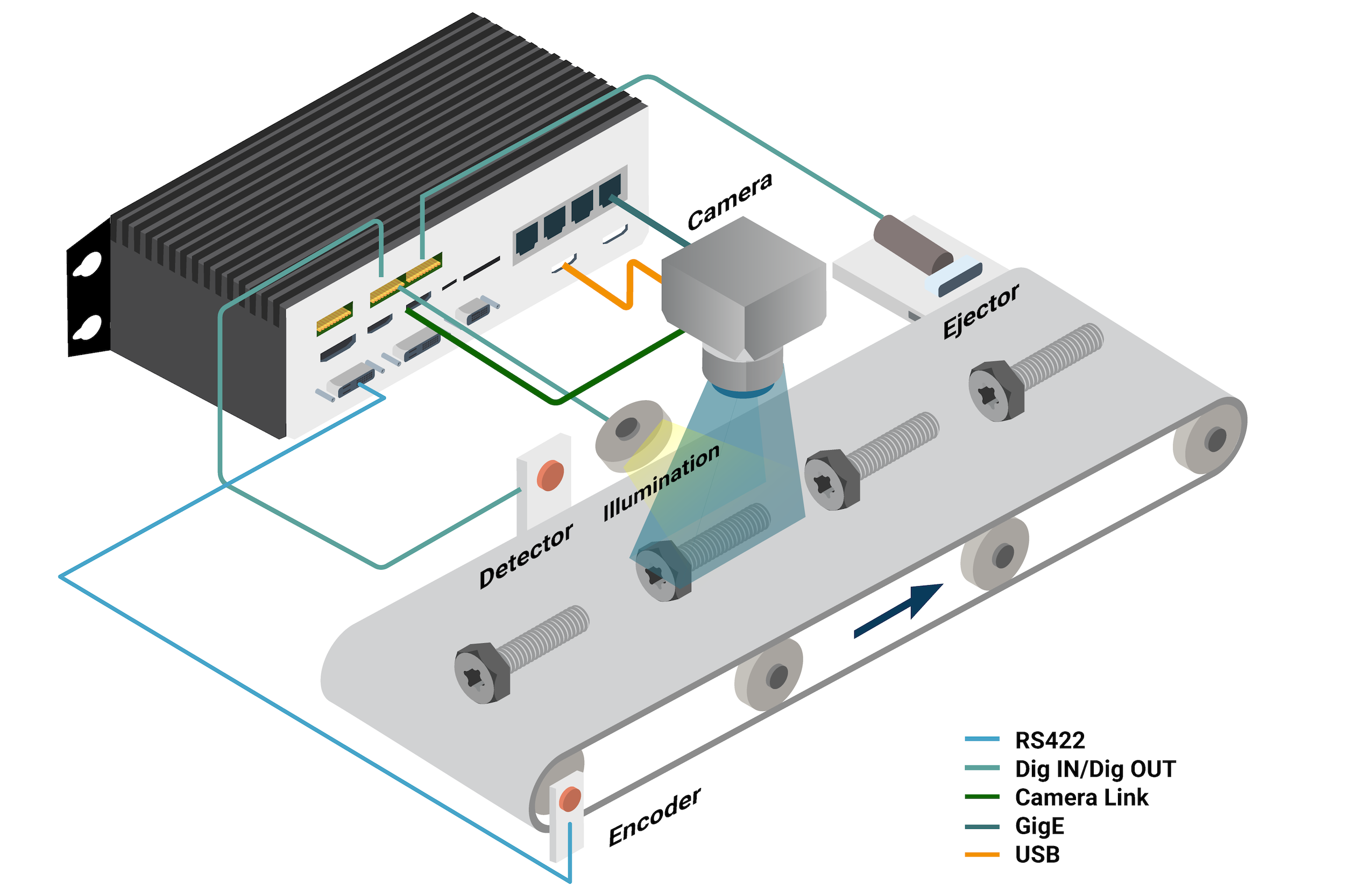

Industrial PCs enable real-time analysis, trigger control, and communication with peripheral components directly within the device. At the core of many systems is the proprietary Real-Time Communication Controller (RTCC), which processes signals with microsecond precision.

By integrating GPU accelerators, the Industrial PC becomes an inference platform for AI applications. For example, deep learning models in production or hyperspectral imaging in the food industry can be implemented efficiently – without external hardware.

Industrial Use from Packaging to Pharma

In the food industry, IMAGO Industrial Computers enable classification of natural products using deep learning. In the pharmaceutical sector, they ensure stable inspection processes under strict validation requirements.

In manufacturing, GPU acceleration supports complex multi-camera setups. In electronics production, they guarantee precise inspection of even the smallest components. And in logistics, they provide flexible code reading for variable packaging sizes – fast, reliable, and industry-compliant.

Why Industrial Computers from IMAGO?

IMAGO Industrial PCs are designed for continuous operation under industrial conditions. Thanks to long-term availability, low power consumption, and robust construction, systems remain low-maintenance and operational for years.

Customers benefit from well-thought-out complete solutions – including drivers, SDKs, and consulting. The close integration of hardware, software, and technical support makes IMAGO a strong partner for series-production image processing solutions.

FAQs about the Industrial PC

What distinguishes IMAGO Industrial PCs from classic IPCs?

IMAGO Industrial PCs integrate frame grabbers, trigger logic, and real-time I/O directly into the device – eliminating the need for external components. This saves space, reduces potential error sources, and enables microsecond-precise processes.

Which interfaces are supported?

GigE Vision, Camera Link, 5GBase-T, RS232/RS485, and fieldbus – IMAGO Industrial PCs offer a wide range of options for cameras and peripheral devices. Interfaces can be customized as needed.

Which operating systems are supported?

Linux and Windows – depending on the model, both platforms are possible. IMAGO provides the right drivers and SDKs for easy integration into existing systems.