News / Press

Image Processing with ViewIT:

Understanding and Applying Basic Functions

Friedberg, 27th August 2025

Using ViewIT’s functions is flexible and intuitive, even without deep programming knowledge.

ViewIT is a powerful yet easy-to-use software for industrial image processing, developed specifically for IMAGO Technologies products. Its comprehensive toolbox not only automates image acquisition and I/O handling but also provides a ready-made user interface (GUI) and powerful debugging functions to accelerate the entire development process.

ViewIT offers users a range of basic functions that can be flexibly configured without extensive programming. This allows for the quick and reliable implementation of key inspection tasks in industrial production. The following section introduces the most important basic functions—each with its principle and typical fields of application.

EDGE DETECTION:

Principle: This function detects abrupt changes in brightness or color, making transitions—the “edges” of objects—visible.

Industrial Application:

- Determining the exact position or size of a workpiece.

- Measuring components such as boreholes or edge positions.

- Checking the quality of milling or cutting processes.

Added Value: Precise position and dimensional control for high product quality.

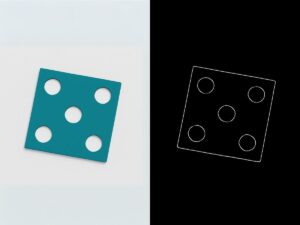

BLOB DETECTION (SPOT AND OBJECT RECOGNITION):

Principle: A “blob” is an area with similar brightness or color. Blob analysis detects and evaluates such connected areas.

Industrial Application:

- Counting objects, e.g., tablets in a blister pack.

- Locating screw heads, holes, or markings.

- Presence detection: Is a label present or is it missing?

Added Value: Reliable control of completeness and object count.

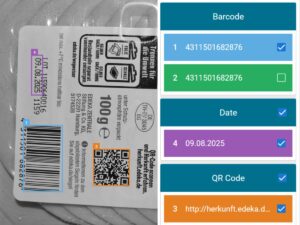

CODE READER:

Principle: Machine-readable codes such as 1D barcodes, 2D DataMatrix, or QR codes are recognized and decoded.

Industrial Application:

- Ensuring the traceability of products (serialization, batch tracking).

- Supporting logistics processes and material flow.

- Quality assurance by checking the readability and correctness of the code.

Added Value: Traceability and process reliability in manufacturing and logistics.

OCR (TEXT RECOGNITION)

Principle: Using optical character recognition, letters and numbers are extracted from images and converted into machine-readable text.

Industrial Application:

- Checking imprints such as expiry dates or serial numbers.

- Verifying the completeness and correctness of labels.

- Document capture in administration and logistics.

Added Value: Automated control of plain text for increased process reliability.

FLEXIBILITY THROUGH COMBINABLE ALGORITHMS:

The basic functions integrated into ViewIT can not only be used individually but also be combined with each other. This allows for the flexible implementation of complex inspection tasks—for example, by using edge and blob analysis together to not only determine the exact position of a workpiece but also to simultaneously detect missing holes or attached parts.

This modular combination creates a powerful tool that users can easily configure—without additional programming and with maximum adaptability to changing tasks.

LEARN MORE ABOUT VIEWIT:

Would you like to learn how ViewIT can optimize your image processing applications? The IMAGO Technologies team would be happy to help you find the optimal solution for your needs.

Press Contact

Anne Krug

Anne Krug

Marketing / Communication

Telephone: +49 6031-684 26 11

marketing@imago-technologies.com