More than a line scan camera: As the only system worldwide, the Vision Cam LM2 combines high-speed, AI, and industrial stability in a smart overall system. As an embedded vision computer with integrated image processing, it delivers fast, precise results – ideal for series applications with the highest demands.

Line Scan Camera

Vision Cam LM2

Description

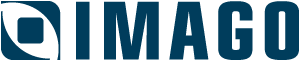

The Vision Cam LM2 is the line scan camera version of the proven Vision Cam XM2 area scan camera system, further developed for high-speed linear processes. It combines line sensor technology, image processing, and AI acceleration in a single compact device. The integrated NVIDIA® Jetson™ Orin module allows Deep Learning applications to run directly on the camera, eliminating the need for an external industrial PC.

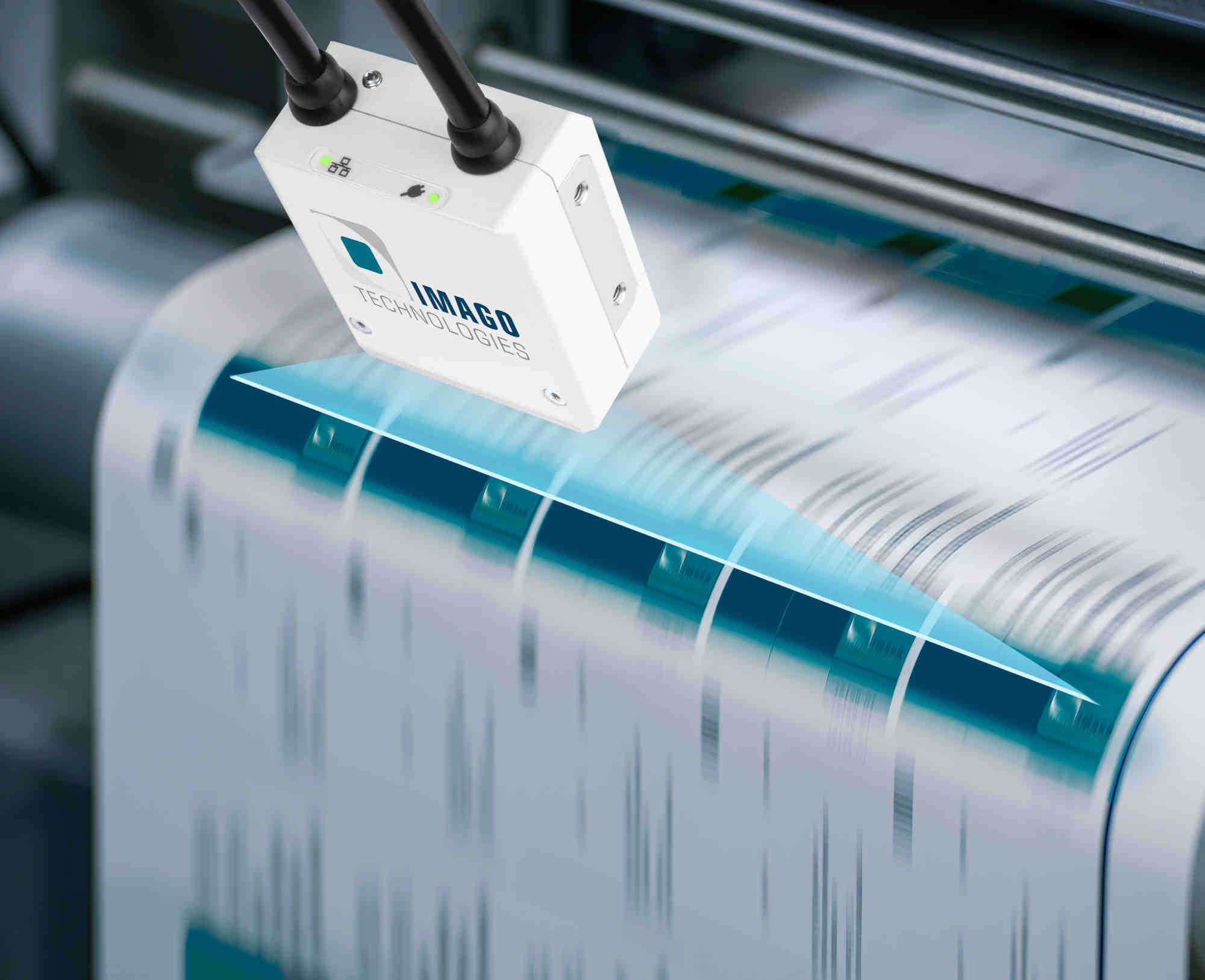

Thanks to its 4K quad-linear sensor, free programmability, and industrial-grade design, the Vision Cam LM2 is perfect for demanding applications in areas such as packaging, food processing, pharmaceuticals, printing, and logistics.

Specific line rates and resolutions can also be realized as an ODM variant upon request. Manufacturers of series machines benefit from its high computing power, long-term availability, and simple integration.

Advantages

Compact and Industrial-Grade

Measuring just 105 × 60 × 64 mm (plus lens tube), the Vision Cam LM2 fits into even the most confined installation spaces. Despite its small size, it contains everything needed for high-performance image processing, including a processor, interfaces, and real-time hardware.

Intelligence Directly in the Camera Housing

The Vision Cam LM2 operates autonomously: it captures, analyzes, and evaluates images directly on the device. This eliminates the need for external PCs, frame grabbers, or additional hardware, reducing wiring complexity and saving space in the control cabinet.

Real-Time via RTCC

The integrated Real-Time Communication Controller (RTCC) precisely synchronizes acquisition speed, illumination, and other system components with the conveyor belt. This ensures microsecond-accurate coordination and reliable communication within the image processing system.

High Line Rate and Resolution

With a line rate of up to 210 kHz and 4 × 4096 pixels, the camera delivers high-resolution color images, ideal for fast-moving processes and wide inspection objects. Even the smallest details are reliably detected.

Freely Programmable on Linux Basis

The camera utilizes Ubuntu Linux for full flexibility in software development with OpenCV, C++, or Python. Its multicore ARM processor and GPU enable the parallel execution of rule-based and AI algorithms. Over 2,000 HALCON operators, including AI functions, are directly usable.

Comprehensive Interfaces

Integrated interfaces—such as the encoder input, Gigabit Ethernet, and digital IOs—allow direct connection to systems, ensuring precise synchronization and seamless system integration.

Long-Term Availability for Series Devices

IMAGO guarantees a stable hardware platform for years to come. This makes the camera ideal for series applications with planning security, including tailored ODM variants as needed.

Support with ViewIT and Engineering

The ViewIT development environment allows applications to be set up quickly by both beginners and professionals. Templates for pattern and edge detection accelerate the getting started, while custom plugins can be flexibly integrated. For more complex requirements, the IMAGO SDK is also available.

Personal Support from Project Start

Especially in early phases, IMAGO actively provides support with technical expertise, reference designs, and concrete recommendations—helping an idea quickly become a functional solution.

Applications

The Vision Cam LM2 is as versatile as the industries in which it’s used. Whether inspecting continuous materials, ensuring traceability in the pharmaceutical industry, or performing high-speed quality control—wherever precision, real-time performance, and flexibility are required, this smart line scan camera shows its full potential.

Target Group

The Vision Cam LM2 is aimed at mechanical engineering companies as well as manufacturers of inspection, packaging, or production systems who want to deploy powerful line scan camera systems flexibly and efficiently. It’s particularly well-suited for product developers who plan to distribute a series product long-term and in a consistent configuration, without constant revalidation or retrofitting.

Thanks to its free programmability, ViewIT Framework, and engineering support, both experienced developers and companies with limited image processing know-how will benefit. A basic understanding of industrial image processing is a prerequisite for project success.

Product Consultation & Quote Request

Send us an inquiry about your desired product. We’ll be happy to provide you with a detailed, personal consultation and create a customized offer just for you.

Line Scan Cameras: Functionality and Synchronization

Unlike area scan cameras, line scan cameras don’t capture images all at once. Instead, they scan objects line by line as they move. Precise synchronization with the object’s movement, often via external trigger pulses or encoders, is crucial for a distortion-free overall image. The required line rate of the camera is determined by the object speed and the desired optical resolution.

Modern Sensor Technology and Data Interfaces

Thanks to modern sensors with high resolution (up to 4,096 pixels), excellent light sensitivity, and powerful interfaces like Camera Link or 5GigE, IMAGO line scan cameras can handle demanding image processing tasks in real time. Choosing the right camera interface is of great importance here, as it directly influences the maximum transferable data rate—a critical factor for high image rates and large data volumes.

FAQs about the Line Scan Camera Vision Cam LM2

What's the difference between a line scan camera and an area scan camera?

The main difference between area scan cameras and line scan cameras is how they capture images. Line scan cameras capture images line by line as the object moves, which is ideal for continuous processes and large inspection widths. Area scan cameras, on the other hand, capture complete images all at once. Line scan cameras generally provide higher resolution and less distortion with consistent movement, especially for fast-moving or endless materials.

Can I run my own algorithms on the line scan camera?

Yes, the Vision Cam LM2 allows you to execute your own algorithms directly on the device. Thanks to the NVIDIA® Jetson™ Orin module, users can run classic image processing or AI models locally—for example, in C++, Python, with access to the ViewIT Framework and the IMAGO SDK.

Which sensor variants are available for the line scan camera?

The Vision Cam LM2 line scan camera comes equipped with a quad-linear sensor (4 × 4096 pixels, RGB + Mono). Other sensor variants or line rates are available as customized ODM variants upon request. This makes the camera flexibly scalable for different resolution requirements.

For which applications is the Vision Cam LM2 not suitable?

The Vision Cam LM2 is not suitable for 3D metrology, robotics-assisted image processing, or cloud-based evaluations. It was designed for classic 2D inspection tasks where AI operates locally, robustly, and in real-time within the machine.